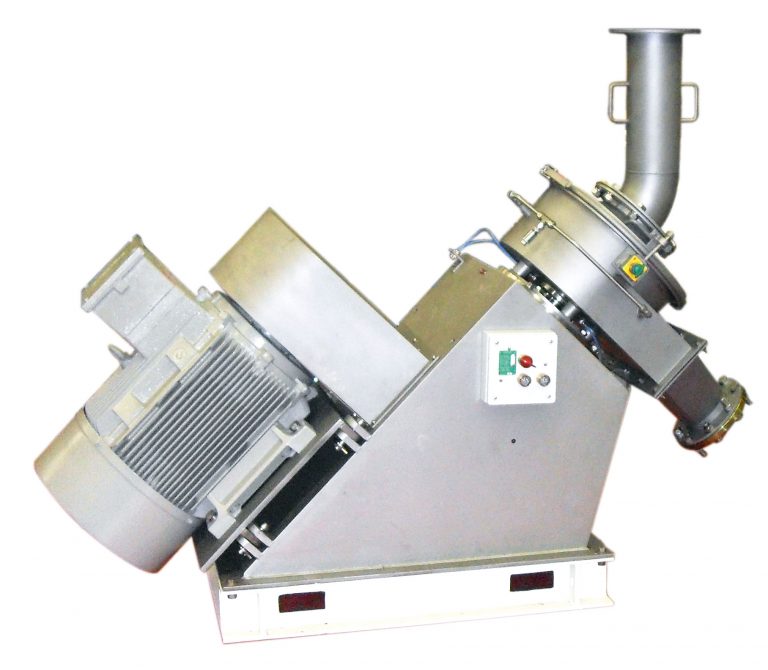

Hosokawa Micron’s Extrudomix is used for continuous and batch mixing of wide-ranging material, from ultra-fine powders and liquids to heavy pastes and plastics.

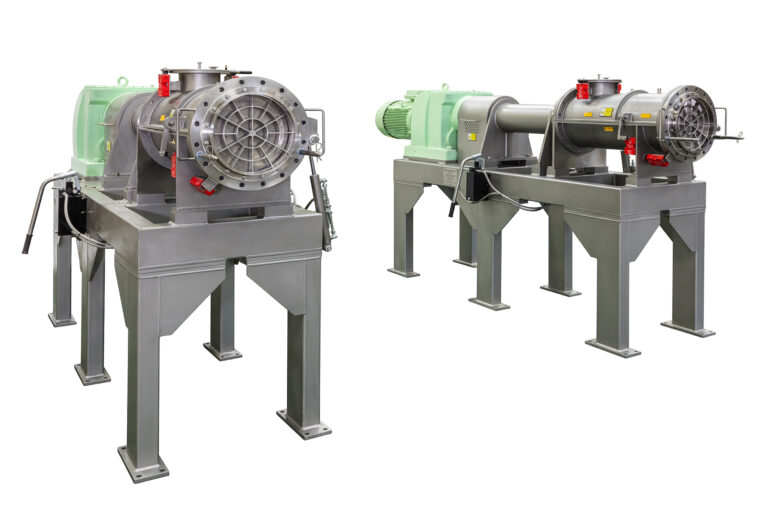

The equipment features discreet zones, incorporating inlets for the introduction of the liquids and solids, with areas containing anvil blocks, rotating paddles and orifice plates throughout, which assist the material to efficiently process through the machine until it is expelled at the discharge.

The Extrudomix features a single, horizontal processing shaft containing radial mixing flights in a spiral configuration that move material from one end of the processing chamber to the other. To provide the back mixing action and successfully expedite the transportation of materials, a system of stationary anvil blocks (attached to the chamber walls) and optional additional internal mixing plates are used to intensify the mixing process and prevent the mass rotation of the material as it transits, allowing for a very high yield of processed material.

Optional jacketed housings or hollow shafts enable the processing material to be heated or cooled, depending on the application requirements.

At the machine discharge, a perforated orifice plate retains the material, regulates the mixing action and, depending on the application, can provide pellets, agglomerates or granules. A simple, but highly effective, sweep blade can also be fitted to process the pellets and granules to a specific length, if required.

Due to the top-bottom open casing, with hinge assembly on the larger models, the operator-friendly Extrudomix can be disassembled easily for cleaning or inspection.